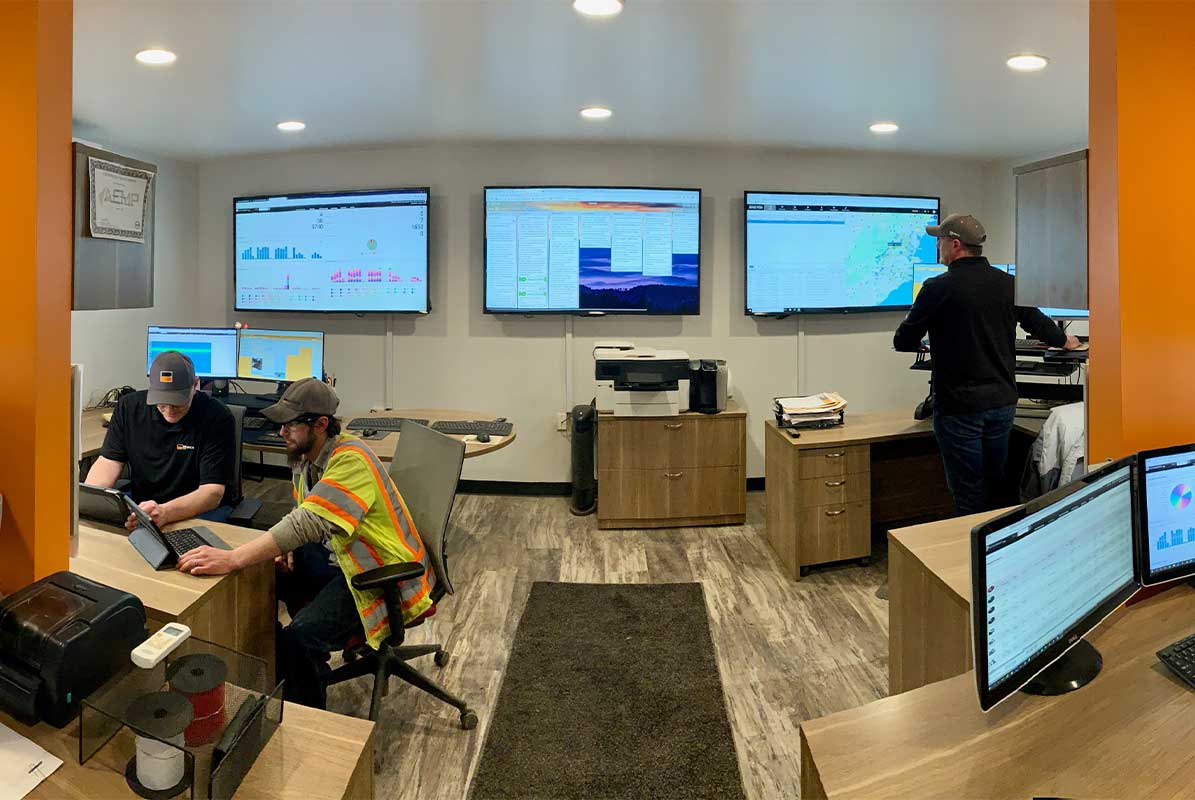

CUTTING-EDGE TECHNOLOGY

GPS & UTS

With the help of GPS and UTS, we utilize a network of base stations to provide a fixed point on which other locations are based.

Branch Civil utilizes both Global Positioning Systems (GPS) and Universal Total Stations (UTS) controlled systems on a daily basis.

In surveying, the UTS system cuts down on the number of crew needed to complete a survey from a three- or four-person operation to a single worker. The user sets up control points and will automatically tell the instrument where the stakes would go, and from there, one person can do the stakeout of the site alone.

UTS also works in machine control of the motor grader to perform a fine grade. The motor grader tracks the model of the job location and elevation and grades the elevation with an accuracy of ¼ to ½ inch.

Our GPS controlled systems use a very similar model, though the vertical tolerance is about 1½ inches and offers a general location and elevation based on the satellite system. We utilize a network of base stations to provide a fixed point on which other locations are based. The information flows from the satellite to the base station and onto the equipment via radio. Even if the base location is out of range, the equipment can still receive instruction by way of a rebroadcast station. We have recently purchased a number of new bulldozers that have the GPS built in, so they are directly connected without the use of a rebroadcast.

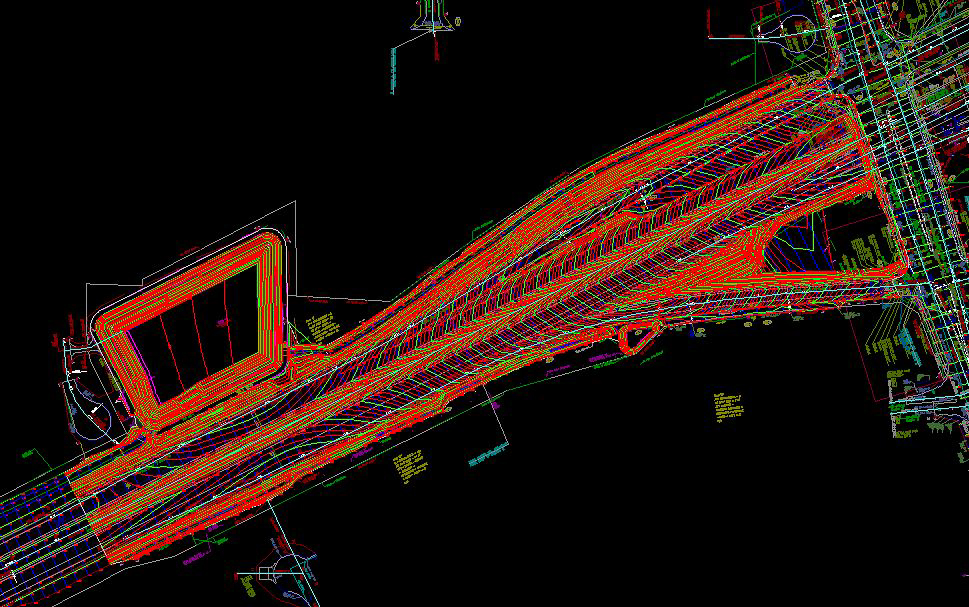

MODELING

MODELING

Plan modeling is taking info from paper plans or 2D CAD files and translating it into 3D data for the GPS controlled machines.

Data modeling is translating design information from paper plans or client provided 2D CAD files to create 3D data for the GPS and/or robotically controlled machines. The 3D data is then uploaded into our GPS enabled bulldozers and motor graders to perform the work.

By utilizing GPS and/or robotically controlled machines, we are able to save many man-hours, stakeout fees, and prevention of having to re-work graded areas. This, in turn, will also save from unnecessary equipment wear, thus saving on fuel and repair costs to the grading fleet.

Branch Civil began utilizing GPS machine control in 2006 with the Battlefield Boulevard Project in Chesapeake, VA. The benefits of using GPS machine control were soon realized to be a great competitive advantage in how the company was able to enhance our work processes and create efficiency.

Part of our quality assurance processes on paving areas of projects is that we survey the constructed curb to develop a new model to assure that the designed paving section is properly constructed to manage to materials to prevent waste. Our fine grading operation utilizing our robotically controlled graders ensure that we repeatedly achieve modeled grades within a 1/8″ tolerance or better.

RECYCLED MATERIALS CRUSHING SITES

When structures made of concrete are demolished or renovated, concrete recycling is a method of utilizing the rubble. Concrete aggregate collected from demolition sites is put through a crushing machine. Aggregate chunks are then sorted by size for a finished product.

Crushed concrete can be used as gravel for construction projects. It can also be used for driveways and roads as a sub-base to be laid down for new concrete and asphalt.

Crushing at the actual construction site using portable crushers reduces construction costs and pollution generated from transporting material from a quarry.

We, at Branch Civil, strive for excellence in the crushing operation. Contact us for your crushing needs.

UNDERGROUND STORM WATER RETENTION

UNDERGROUND STORM WATER RETENTION

Underground Storm Water Retention and Detention Systems are a key component of modern site development. Storm water retention and detention systems are present in the industry as either above ground ponds or as subsurface piping. The former is the least expensive method, though it is the most inefficient use of developable land, is prone to early siltation and clogging, and poses long-term aesthetic problems such as insect breeding, weed growth, and odor and refuse issues. By comparison, subsurface retention and detention systems use available land efficiently while introducing low maintenance costs and posing little or no aesthetic problems.

Detention systems are employed on a site to reduce the quantity of stormwater runoff leaving a site by temporarily storing the runoff that exceeds a site’s allowable discharge rate and releasing it slowly over time.

Infiltration systems are incorporated to reduce the volume of stormwater runoff being discharged from a site. This runoff reduction strategy is a major part of a low-impact development design.

A storm water retention system differs from a detention solution because it allows the water to slowly discharge into the soil instead of detaining it for a time before it is released.

The components of these systems typically involve underground tanks, arches, or contained pipe systems; in conjunction with geo-fabrics, filters, and aggregate layers. Branch Civil has installed a wide variety of these systems over the years and can help determine the most feasible system for your site. All of these systems are designed to help avoid the flooding and erosion that can be caused by excess runoff, and with the integrated filtration elements, you can make sure that the discharged water will not have an adverse effect on our streams, rivers or wetlands, and all the aquatic life those places support. With our experience and capabilities installing and sourcing these systems with our industry partners, Branch Civil is ready to help make the most out of your development, while keeping within the bounds of desirable environmental impacts.

SOCK DRAINS

Sock Drains perform one critical function: filter water being drained into the perforated pipe from surrounding soils.

Pipe drain sleeves, also known as sock drains, have been used in the construction industry for many years. They are made up of a synthetic fiber and are slipped onto the exterior of a perforated pipe to perform one critical function: filter water being drained into the perforated pipe from surrounding soils.

Sock drains improve and maintain water flow by preventing accumulations of sediment in the perforated pipe, allowing for proper drainage and “drying out” of project-critical areas, such as borrow pits and stormwater management ponds. By preventing blockage of the perforated pipe, the life of the drainage system is extended drastically, which cuts down on cost and allows for resources to be allocated elsewhere.

This sock drain system is currently being utilized on our Dominion Boulevard Improvements project in Chesapeake, VA. One of our subcontractors installed this drainage system at our borrow pit, which will yield approximately 400,000 cubic yards of quality material. Having the system in place has allowed us to mine the material directly from the ground and immediately place it where required on the project. In the absence of the sock drain system, it would be necessary to mine the material, stockpile it to allow moisture to drain/evaporate, and then place it where required. In instances where the material is saturated, it would be necessary to spread the material to allow for more efficient “drying out” before placing.

This drainage system has proven vital to our operations, as it allows for uninterrupted mining of borrow material. We feel it is an excellent tool and will continue to use it on current and future projects.

WHAT WE DO

Site Development

The foundation that all construction projects are built upon. As a leader in site development, we have built many of the largest and most challenging projects in the region.

Heavy / Highway Construction

We have successfully delivered large civil construction projects for the North Carolina and Virginia Departments of Transportation and public and private sector clients.